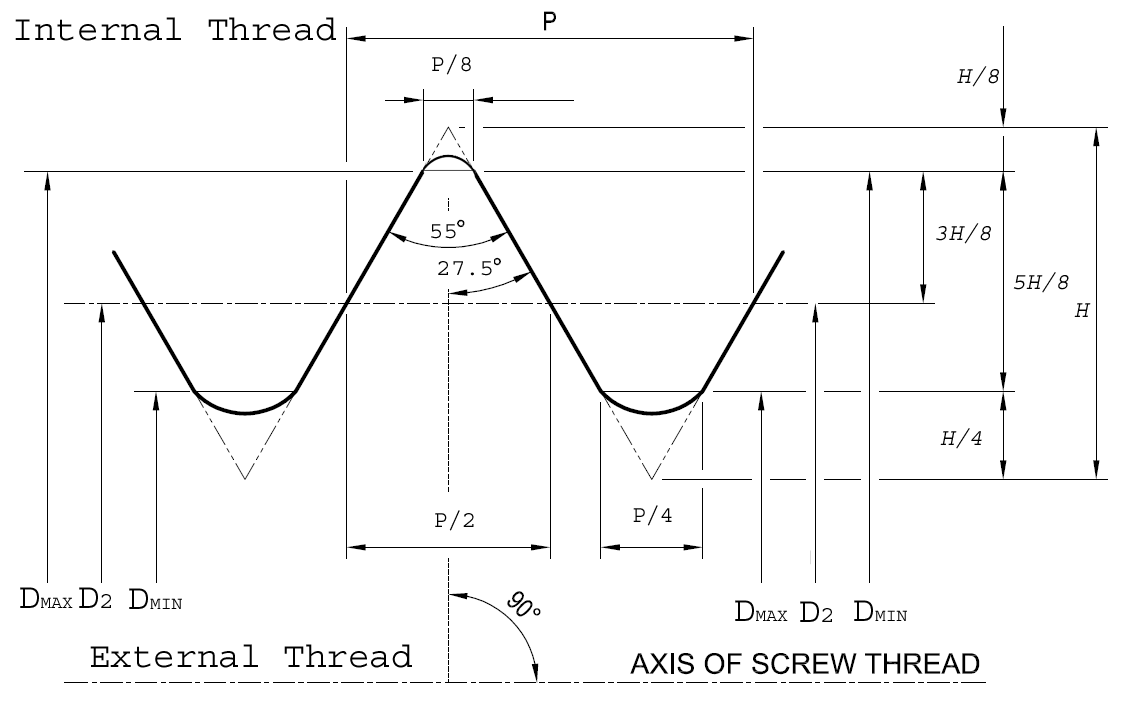

The Whitworth thread was the world's first national screw thread standard devised and specified by Joseph Whitworth in 1841. Until then, the only standardization was what little had been done by individual people and companies. Some of the companies' in-house standards spreading a bit within their industries. Whitworth's new standard specified a 55° thread angle and a thread depth of 0.640327p and a radius of 0.137329p. Where p is the pitch. The thread pitch increases with the diameter in steps specified on a chart.

The Whitworth thread system was later to be adopted as a British Standard to become British Standard Whitworth (BSW). An example of the use of the Whitworth thread is the Royal Navy's Crimean War gunboats. These are the first instance of mass-production techniques being applied to marine engineering. The following quotation from the obituary from The Times of 24 January 1887 to Sir Joseph Whitworth (1803–1887) shows.

The British Standard Fine (BSF) standard has the same thread angle as the BSW but has a finer thread pitch and smaller thread depth. This is more like the modern "mechanical" screw and was used for fine machinery and steel bolts.

The British Standard Cycle (BSC) standard which replaced the Cycle Engineers' Institute (CEI) standard was used on British bicycles and motorcycles. It uses a thread angle of 60° compared to the Whitworth 55° and very fine thread pitches.

TPI stands for Threads Per Inch, Which means the total number of threads per inch measured along the length of a fastener. TPI is used only with American fasteners. Metric Fasteners use a thread Pitch. In general, smaller fasteners have finer threads, so the thread count is higher.

The thread pitch is the distance between threads expressed in millimeters. In general, smaller fasteners have finer threads, so they have a lower thread pitch.

| Nominal Inch | TPI | Pitch | Thread Depth | Major Diameter | Effective Diameter | Minor Diameter | Tap Drill Size (mm) |

|---|---|---|---|---|---|---|---|

| 1/8 | 40 | 0.025 | 0.016 | 0.125 | 0.109 | 0.0903 | 2.55 mm |

| 3/16 | 24 | 0.04167 | 0.0267 | 0.1875 | 0.1608 | 0.1341 | 3.70 mm |

| 1/4 | 20 | 0.05 | 0.032 | 0.25 | 0.218 | 0.186 | 5.10 mm |

| 5/16 | 18 | 0.05556 | 0.0356 | 0.3125 | 0.2769 | 0.2413 | 6.50 mm |

| 3/8 | 16 | 0.0625 | 0.04 | 0.375 | 0.335 | 0.295 | 7.90 mm |

| 7/16 | 14 | 0.07143 | 0.0457 | 0.4375 | 0.3918 | 0.3461 | 9.30 mm |

| 1/2 | 12 | 0.08333 | 0.0534 | 0.5 | 0.4466 | 0.3932 | 10.50 mm |

| 9/16 | 12 | 0.08333 | 0.0534 | 0.5625 | 0.5091 | 0.4557 | 12.10. mm |

| 5/8 | 11 | 0.09091 | 0.0582 | 0.625 | 0.5668 | 0.5086 | 13.50 mm |

| 11/16 | 11 | 0.09091 | 0.0582 | 0.6875 | 0.6293 | 0.5711 | 15.00 mm |

| 3/4 | 10 | 0.1 | 0.064 | 0.75 | 0.686 | 0.622 | 16.25 mm |

| 7/8 | 9 | 0.11111 | 0.0711 | 0.875 | 0.8039 | 0.7328 | 19.25 mm |

| 1 | 8 | 0.125 | 0.08 | 1 | 0.92 | 0.84 | 22.00 mm |

| 1 1/8 | 7 | 0.14286 | 0.0915 | 1.125 | 1.0335 | 0.942 | 24.75 mm |

| 1 1/4 | 7 | 0.14286 | 0.0915 | 1.25 | 1.1585 | 1.067 | 28.00 mm |

| 1 1/2 | 6 | 0.16667 | 0.1067 | 1.5 | 1.3933 | 1.2866 | 33.50 mm |

| 1 3/4 | 5 | 0.2 | 0.1281 | 1.75 | 1.6219 | 1.4938 | 39.00 mm |

| 2 | 4.5 | 0.22222 | 0.1423 | 2 | 1.8577 | 1.7154 | 44.50 mm |