The Unified Thread Standard (UTS) defines a standard thread form and series along with allowances, tolerances, and designations, for screw threads commonly used in the United States and Canada.

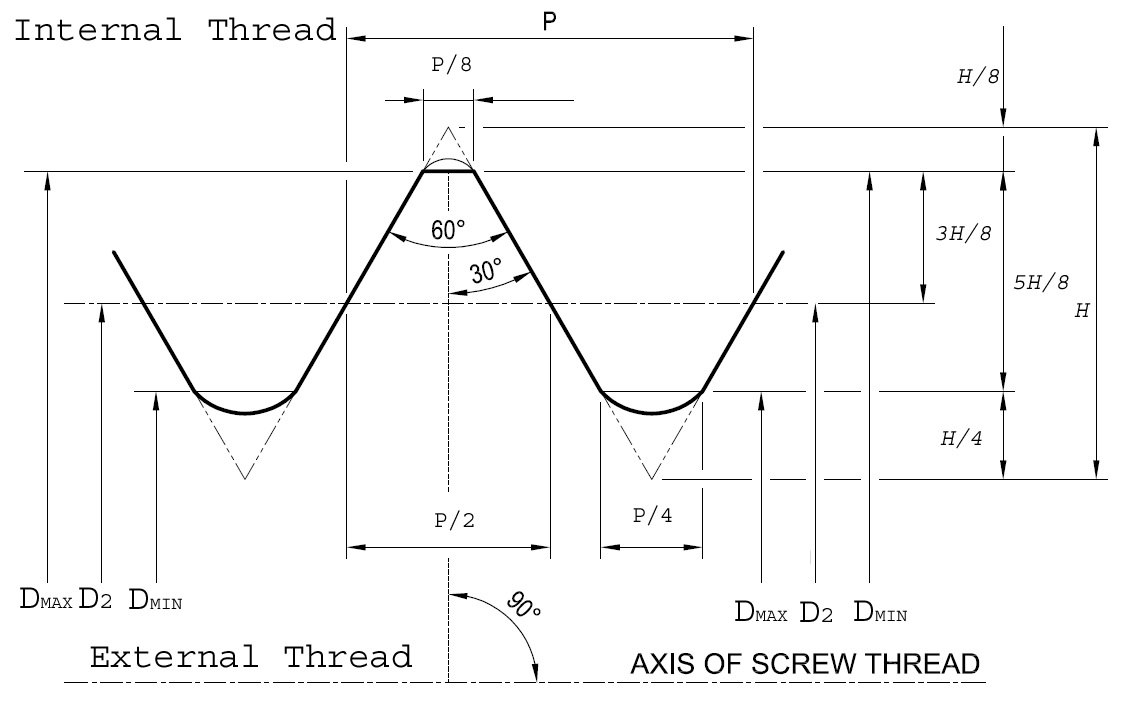

It is the main standard for bolts, nuts, and a wide variety of other threaded fasteners used in these countries. It has the same 60 °profile as the ISO metric screw thread, but the characteristic dimensions of each UTS thread (outer diameter and pitch) were chosen as an inch fraction rather than a millimeter value. The UTS is currently controlled by ASME/ANSI in the United States.

A classification system exists for ease of manufacture and interchangeability of fabricated threaded items. Most (but certainly not all) threaded items are made to a classification standard called the Unified Screw Thread Standard Series. This system is analogous to the fits used with assembled parts.

Class 1 threads are loosely fitting threads intended for ease of assembly or use in a dirty environment.

Class 2 threads are the most common. They are designed to maximize strength considering typical machine shop capability and machine practice.

Class 3 threads are used for closer tolerances.

Class 4 thread fit is even tighter than a Class 3.

Class 5 fit is not a loose thread. It is an interference thread, used on items like spring shackles on an automobile.

The letter suffix "A" or "B" denotes whether the threads are external or internal, respectively. Classes 1A, 2A, 3A apply to external threads; Classes 1B, 2B, 3B apply to internal threads.

Thread class refers to the acceptable range of pitch diameter for any given thread. The pitch diameter is indicated as Dp in the figure shown above. Several methods are used to measure the pitch diameter. The most common method used in production is by way of a go/no go gauge.

TPI stands for Threads Per Inch, Which means the total number of threads per inch measured along the length of a fastener. TPI is used only with American fasteners. Metric Fasteners use a thread Pitch. In general, smaller fasteners have finer threads, so the thread count is higher.

The thread pitch is the distance between threads expressed in millimeters. In general, smaller fasteners have finer threads, so they have a lower thread pitch.

| Major diameter in inch | Thread density (d), Threads Per Inch and Thread Pitch (p) | Preferred cutting tap drill size | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Coarse (UNC) | Fine (UNF) | Extra fine (UNEF) | ||||||||

| inch | diameter | TPI | Pitch | TPI | Pitch | TPI | Pitch | Coarse | Fine | Extra fine |

| #0 | 0.0600 | - | - | 80 | 0.012500 | - | - | - | 3/64 | - |

| #1 | 0.0730 | 64 | 0.015625 | 72 | 0.013888 | - | - | #53 (0.060) | #53 (0.060) | - |

| #2 | 0.0860 | 56 | 0.017857 | 64 | 0.015625 | - | - | #50 (0.070) | #50 (0.070) | - |

| #3 | 0.0990 | 48 | 0.020833 | 56 | 0.017857 | - | - | #47 (0.079) | #45 (0.082) | - |

| #4 | 0.1120 | 40 | 0.025000 | 48 | 0.020833 | - | - | #43 (0.089) | #42 (0.094) | - |

| #5 | 0.1250 | 40 | 0.025000 | 44 | 0.022727 | - | - | #38 (0.102) | #37 (0.104) | - |

| #6 | 0.1380 | 32 | 0.031250 | 40 | 0.025000 | - | - | #36 (0.107) | #33 (0.113) | - |

| #8 | 0.1640 | 32 | 0.031250 | 36 | 0.027778 | - | - | #29 (0.136) | #29 (0.136) | - |

| #10 | 0.1900 | 24 | 0.041667 | 32 | 0.031250 | - | - | #25 (0.150) | #21 (0.159) | - |

| #12 | 0.2160 | 24 | 0.041667 | 28 | 0.035714 | 32 | 0.031250 | #16 (0.177) | #14 (0.182) | 3/16 (0.187) |

| 1/4 | 0.2500 | 20 | 0.050000 | 28 | 0.035714 | 32 | 0.031250 | #7 (0.201) | #3 (0.213) | 7/32 (0.218) |

| 5/16 | 0.3125 | 18 | 0.055556 | 24 | 0.041667 | 32 | 0.031250 | F (.257) | I (.272) | 9/32 (0.281) |

| 3/8 | 0.3750 | 16 | 0.062500 | 24 | 0.041667 | 32 | 0.031250 | 5/16 (0.312) | Q (.332) | 11/32 (0.343) |

| 7/16 | 0.4375 | 14 | 0.071428 | 20 | 0.050000 | 28 | 0.035714 | U (.368) | 25/64 (0.390) | Y (.404) |

| 1/2 | 0.5000 | 13 | 0.076923 | 20 | 0.050000 | 28 | 0.035714 | 27/64 (0.421) | 29/64 (0.453) | 15/32 (0.468) |

| 9/16 | 0.5625 | 12 | 0.083333 | 18 | 0.055556 | 24 | 0.041667 | 31/64 (0.484) | 1/2 (0.5) | 33/64 (0.515) |

| 5/8 | 0.6250 | 11 | 0.090909 | 18 | 0.055556 | 24 | 0.041667 | 17/32 (0.531) | 9/16 (0.562) | 37/64 (0.578) |

| 3/4 | 0.7500 | 10 | 0.100000 | 16 | 0.062500 | 20 | 0.050000 | 21/32 (0.656) | 11/16 (0.687) | 45/64 (0.703) |

| 7/8 | 0.8750 | 9 | 0.111111 | 14 | 0.071428 | 20 | 0.050000 | 49/64 (0.765) | 51/64 (0.796) | 53/64 (0.828) |

| 1 | 1.0000 | 8 | 0.125000 | 12(*) | 0.083333 | 20 | 0.050000 | 7/8 (0.857) | 59/64 (0.921) | 61/64 (0.953) |

| Major diameter in mm | Thread density (d), Threads Per Inch and Thread Pitch (p) | Preferred cutting tap drill size | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Coarse (UNC) | Fine (UNF) | Extra fine (UNEF) | ||||||||

| inch | diameter | TPI | Pitch | TPI | Pitch | TPI | Pitch | Coarse | Fine | Extra fine |

| #0 | 1.5240 | - | - | 80 | 0.3175 | - | - | - | 3/64 | - |

| #1 | 1.8542 | 64 | 0.3969 | 72 | 0.3528 | - | - | #53 (1.524) | #53 (1.524) | - |

| #2 | 2.1844 | 56 | 0.4536 | 64 | 0.3969 | - | - | #50 (1.778) | #50 (1.778) | - |

| #3 | 2.5146 | 48 | 0.5292 | 56 | 0.4536 | - | - | #47 (2.006) | #45 (2.083) | - |

| #4 | 2.8448 | 40 | 0.6350 | 48 | 0.5292 | - | - | #43 (2.260) | #42 (2.387) | - |

| #5 | 3.1750 | 40 | 0.6350 | 44 | 0.5773 | - | - | #38 (2.5908) | #37 (2.6416) | - |

| #6 | 3.5052 | 32 | 0.7938 | 40 | 0.6350 | - | - | #36 (2.717) | #33 (2.870) | - |

| #8 | 4.1656 | 32 | 0.7938 | 36 | 0.7056 | - | - | #29 (3.454) | #29 (3.454) | - |

| #10 | 4.8260 | 24 | 1.0583 | 32 | 0.7938 | - | - | #25 (3.810) | #21 (4.038) | - |

| #12 | 5.4864 | 24 | 1.0583 | 28 | 0.9071 | 32 | 0.7938 | #16 (4.496) | #14 (4.623) | 3/16 (4.762) |

| 1/4 | 6.3500 | 20 | 1.2700 | 28 | 0.9071 | 32 | 0.7938 | #7 (5.105) | #3 (5.410) | 7/32 (5.556) |

| 5/16 | 7.9375 | 18 | 1.4111 | 24 | 1.0583 | 32 | 0.7938 | F (6.527) | I (6.908) | 9/32 (7.143) |

| 3/8 | 9.5250 | 16 | 1.5875 | 24 | 1.0583 | 32 | 0.7938 | 5/16 (7.937) | Q (8.433) | 11/32 (8.731) |

| 7/16 | 11.1125 | 14 | 1.8143 | 20 | 1.2700 | 28 | 0.9071 | U (9.347) | 25/64 (9.921) | Y (10.261) |

| 1/2 | 12.7000 | 13 | 1.9538 | 20 | 1.2700 | 28 | 0.9071 | 27/64 (10.715) | 29/64(11.509) | 15/32 (11.906) |

| 9/16 | 14.2875 | 12 | 2.1167 | 18 | 1.4111 | 24 | 1.0583 | 31/64 (12.303) | 1/2 (12.7) | 33/64 (13.096) |

| 5/8 | 15.8750 | 11 | 2.3091 | 18 | 1.4111 | 24 | 1.0583 | 17/32 (13.493) | 9/16 (14.287) | 37/64 (14.684) |

| 3/4 | 19.0500 | 10 | 2.5400 | 16 | 1.5875 | 20 | 1.2700 | 21/32 (16.668) | 11/16 (17.462) | 45/64 (17.859) |

| 7/8 | 22.2250 | 9 | 2.8222 | 14 | 1.8143 | 20 | 1.2700 | 49/64 (19.446) | 51/64 (20.240) | 53/64 (21.034) |

| 1 | 25.4000 | 8 | 3.1750 | 12(*) | 2.1167 | 20 | 1.2700 | 7/8 (22.225) | 59/64 (23.415) | 61/64 (24.209) |